R&D

Core Process

- Categories:科技研发

- Time of issue:2020-06-07 00:00:00

- Views:0

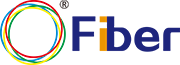

(一)Pultrusion Technology

The core competitiveness of Fiber is pultrusion technology. Our products are widely used in various fields at home and abroad.

Process Flow:

Pultrusion is an automated, continuous process of producing fiber reinforced composites using heated dies to give the parts the desired cross-sectional shape. The standard pultrusion process combines longitudinal and transverse reinforcement to produce composites by injecting reinforcement and polymer resin and curing them in a mold. In addition to maintaining material supply, the production process requires little manual operation and is cost-effective in terms of waste.

The reinforcement material is pulled through the device container for resin injection, and the resin impregnated reinforcement material is pulled through the molding guide before entering the mold, so that the reinforcement material can achieve the pre-designed mechanical properties when entering the mold. The forming rail can also remove extra resin, thus reducing the hydraulic pressure caused by material entering the mold. The preformed shape is pulled through the heated mold to give the laminate the final cross-sectional shape. The mold will initiate an exothermic reaction in the formulated resin to complete curing.

The finished profile is continuously pulled out from the mold by the traction device, and then the profile is cut into a certain length of finished product as required by the cutting machine.

Process Flow Diagram

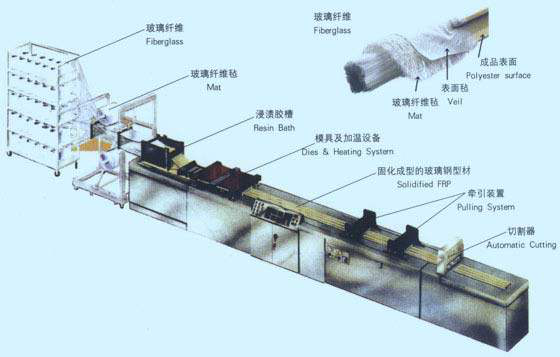

Pultrusion products of polyurethane resin

Fiber currently mainly uses the thermosetting resins for pultrusion. The thermosetting resins mainly include unsaturated polyester resin, vinyl ester resin, epoxy resin, phenolic resin, and polyurethane resin, etc. The newly developed technology for pultrusion with polyurethane resin has the following advantages:

1. Using polyurethane pultrusion, glass fiber roving can be used to replace glass fiber mat. The abolition of the glass fiber mat reduces the cost of raw materials and the labor cost for operating the mat.

2. Polyurethane pultrusion products can be used in some new applications where polyester resin is not competent, replacing steel and aluminum in construction, infrastructure and transportation markets.

3. It is simple, convenient and economical to convert the original pultrusion system into polyurethane pultrusion system without large investment.

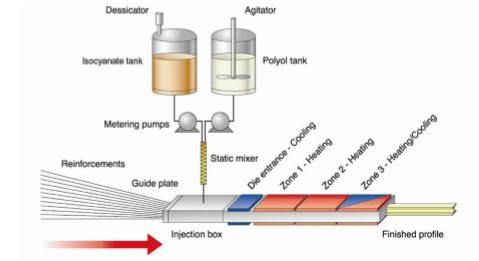

(二) Compression Molding Process

Compression molding is a molding method of thermosetting composite materials. A certain amount of molding compound is put into a pair of metal molds. Under a certain temperature and pressure, the molding compound is heated and plasticized in the mold cavity, flows under pressure and fills the mold cavity to form shape. During the molding process, heating and pressure are needed, so that the plasticization of the molding compound produces a flow to fill the mold cavity and make the resin curing reaction. In the process that the composite molding compound flows to fill the cavity, not only the resin flows, but also the reinforcement material flows, so that the resin and fiber fill all parts of the mold cavity at the same time. Therefore, the compression molding process requires a higher molding than other process methods, which belongs to high pressure molding. It requires compression molding dies with high strength, high precision and high temperature resistance. The compression molding method has the advantages of high production efficiency, accurate product size and smooth surface, which is suitable for mass production.

Process Flow:

Scan the QR code to read on your phone

Jiangsu Fiber Composite Co., Ltd.

Tel:+86 -025-86798609

MP:+86-139-0518-7818

Web:www.jsfiberwell.com

Mail:alex@jsfiberwell.com

P.C.:224700

Add: No.888 High-tech Hydraulic Technology Park, Center Road,

Jianhu, Yancheng, Jiangsu, P.R.C.

Jiangsu Fiber Composite Co., Ltd. Nanjing Branch

Tel: +86 -025-86798609

MP +86-139-0518-7818

Web:www.jsfiberwell.com

Mail:alex@jsfiberwell.com

P.C.:210012

Add: Room G-712, Zendai Himalaya Centre, No 10 Minzhi Rd, Nanjing, Jiangsu, P.R.C.