Rockbolt accessories manufacturer takes you to understand the principle of bolt support

- Categories:news

- Author:

- Origin:

- Time of issue:2021-12-06

- Views:0

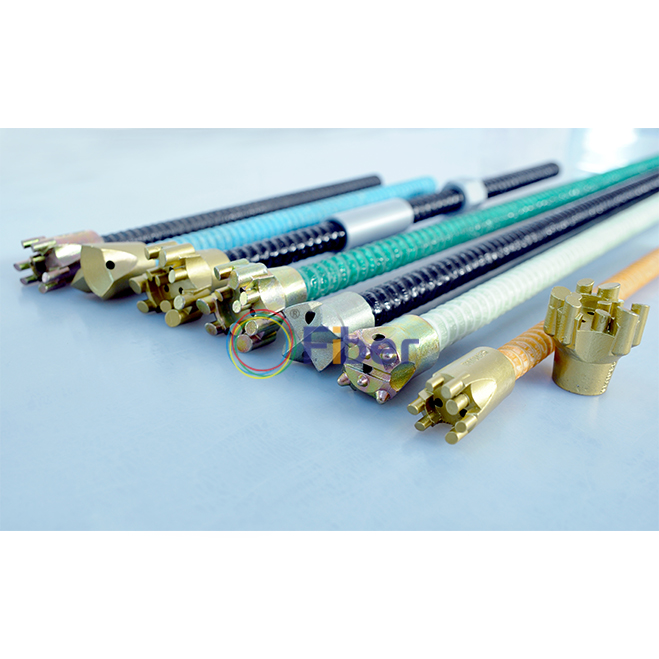

(Summary description)Rockbolt accessories manufacturer will take you today to understand the principle of bolt support.

Rockbolt accessories manufacturer takes you to understand the principle of bolt support

(Summary description)Rockbolt accessories manufacturer will take you today to understand the principle of bolt support.

- Categories:news

- Author:

- Origin:

- Time of issue:2021-12-06

- Views:0

Rockbolt accessories manufacturer will take you today to understand the principle of bolt support.

Principle of bolt support:

1. Suspension function: The Rockbolt accessories manufacturer tells you that the anchor rod hangs the weak rock layer on the firm and stable rock layer to prevent the layer from falling off. The direct roof of the coal seam roadway is generally weak and thin, and it is easy to fall off the layer, while the old roof above it is relatively strong. The anchor rod can reach the old roof through the direct roof, and the direct roof is anchored on the old roof.

2. The role of composite beam: Rockbolt accessories manufacturer tells you that in the roof of the layered rock layer, a series of bolts are used to anchor the thin layer of rock within the length of the bolt into a rock composite beam, thereby improving its bearing capacity. Under the same load, the deflection and internal stress of the composite beam are greatly reduced compared with the uncombined plate beam.

3. Surrounding rock reinforcement: the rock in the deep surrounding rock of the roadway is under triaxial compression, while the rock near the periphery of the roadway is under biaxial stress. The strength is less than the former, so it is easy to break and lose stability. The manufacturer of Rockbolt accessories tells you that after the surrounding rock of the roadway is anchored by the bolt, the surface rock partly restores the state of triaxial stress, which increases its own strength. In addition, the bolt can also increase the shear resistance of the weak surface of the rock, making the roadway The surrounding rock is not easy to damage and lose stability, which is called wall rock reinforcement.

4. The effect of squeezing connection: the anchor rod squeezes the surrounding rock of the roadway, applies prestress to the rock, prevents the continuous expansion of the crack, and can also play the role of squeezing connection and reinforcement for loose rock. The Rockbolt accessories manufacturer tells you that a simple and interesting experiment has been done abroad: a rectangular wooden box is filled with small gravel, and they are anchored with a simulated anchor rod. After the anchor rod is tightened, the wooden box is turned over and filled. The small gravel could not be poured out. Through the prestress of the anchor rod, a kind of lateral squeeze frictional resistance can be generated between the crushed stones that have no adhesion to each other, which is sufficient to support the weight of the crushed stone itself without falling, as if the crushed stones are connected to each other. It looks the same.

5. The role of squeezing and strengthening the arch: continue the above test, the small gravel bolted with anchor rods, not only are they squeezed and connected together enough to support their own weight, but it can also be used as a load-bearing structure. Support extra load. The Rockbolt accessories manufacturer tells you that through the loading test, it is found that the loaded anchored crushed stone components will have a tensile stress area between the anchor pads, causing the small crushed stones in this area to loosen and fall off and form a dome. When the load increases, the dome will expand and cause the collapse of the load-bearing structure. In order to prevent this situation, the thin wire mesh is stretched under the anchor plate to greatly improve the supporting capacity of the bolt. When the load is increased to a considerable size (repeated loading), the damage starts when the wire mesh is cut. The Rockbolt accessories manufacturer tells you the above test instructions. Under the action of prestress, the loose gravel surrounds each bolt to form a cylindrical extrusion zone or compressive stress zone with conical ends at both ends. In the bolt group arranged in the system, these extrusions The nip constitutes a fairly wide and uniform compression reinforcement belt, which is equivalent to a load-bearing structure and supports a considerable load. The Rockbolt accessories manufacturer tells you that after installing the bolts arranged in groups and radially around the roadway, an arch compression zone or squeeze reinforcement arch is formed within a certain thickness of the surrounding rock, which makes the surrounding rock of the roadway change from the original The "load" on the support becomes a "bearing" structure. The thickness of the arched compression belt is related to the length and spacing of the anchor rods.

Scan the QR code to read on your phone

Jiangsu Fiber Composite Co., Ltd.

Tel:+86 -025-86798609

MP:+86-139-0518-7818

Web:www.jsfiberwell.com

Mail:alex@jsfiberwell.com

P.C.:224700

Add: No.888 High-tech Hydraulic Technology Park, Center Road,

Jianhu, Yancheng, Jiangsu, P.R.C.

Jiangsu Fiber Composite Co., Ltd. Nanjing Branch

Tel: +86 -025-86798609

MP +86-139-0518-7818

Web:www.jsfiberwell.com

Mail:alex@jsfiberwell.com

P.C.:210012

Add: Room G-712, Zendai Himalaya Centre, No 10 Minzhi Rd, Nanjing, Jiangsu, P.R.C.