Which surface treatment method to choose for FRP walkway

- Categories:news

- Author:

- Origin:

- Time of issue:2021-06-18

- Views:0

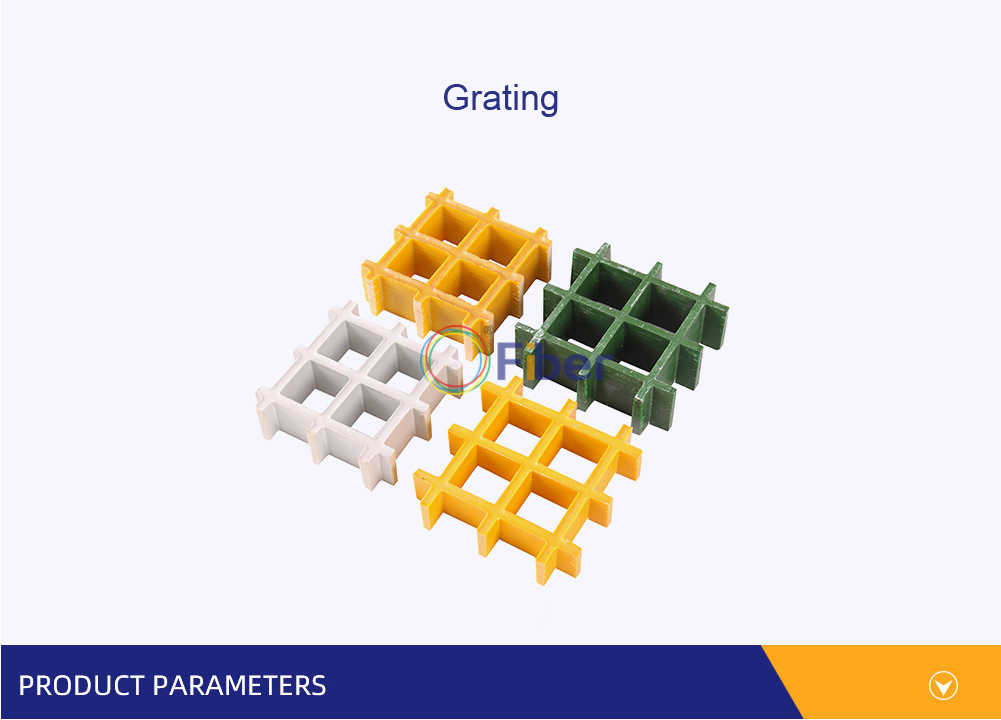

(Summary description)Which surface treatment method should I choose for FRP walkway? The FRP walkway is made of steel, and steel is easy to rust in the air, water or soil, or even completely damaged. It is understood that the annual steel loss due to corrosion accounts for about 1/10 of the entire steel output, so people have developed the galvanizing process.

Which surface treatment method to choose for FRP walkway

(Summary description)Which surface treatment method should I choose for FRP walkway? The FRP walkway is made of steel, and steel is easy to rust in the air, water or soil, or even completely damaged. It is understood that the annual steel loss due to corrosion accounts for about 1/10 of the entire steel output, so people have developed the galvanizing process.

- Categories:news

- Author:

- Origin:

- Time of issue:2021-06-18

- Views:0

Which surface treatment method should I choose for FRP walkway? The FRP walkway is made of steel, and steel is easy to rust in the air, water or soil, or even completely damaged. It is understood that the annual steel loss due to corrosion accounts for about 1/10 of the entire steel output, so people have developed the galvanizing process.

The galvanized steel FRP walkway is beautiful in craftsmanship and has a certain decorativeness. Galvanizing includes hot-dip galvanizing and electro-galvanizing, both of which can be applied to the surface treatment of FRP walkway. Although both can be applied, the essential difference between the two is still different.

Which surface treatment method should I choose for FRP walkway?

1. In terms of price: the price of electro-galvanized steel grating is low, and the price of hot-dip galvanized steel grating is 3-4 times higher than that of electro-galvanized steel.

2. Environmental pollution: hot-dip galvanizing produces less "three wastes" in the production process than electro-galvanizing, and has less impact on the environment.

3. In terms of production efficiency: the production efficiency of hot-dip galvanizing is particularly high, and the residence time of the parts in the hot-dip galvanizing tank is relatively short.

4. Usage: hot-dip galvanized steel grating has thick zinc-zinc coating, fine crystals, uniformity and no porosity, good corrosion resistance, slower corrosion in acid, alkali and other mists, which can effectively protect the steel substrate than electroplating Zinc has a long service life and can be used for an additional 40 years.

Hot-dip galvanized FRP walkway not only has the corrosion resistance of electro-galvanized, but also has strong corrosion resistance that can not be compared with electro-galvanized. Hot-dip galvanizing can make a thicker and dense pure zinc layer cover the surface of steel. Avoid contact between the steel substrate and any corrosive solution, and protect the steel substrate from corrosion.

Scan the QR code to read on your phone

Jiangsu Fiber Composite Co., Ltd.

Tel:+86 -025-86798609

MP:+86-139-0518-7818

Web:www.jsfiberwell.com

Mail:alex@jsfiberwell.com

P.C.:224700

Add: No.888 High-tech Hydraulic Technology Park, Center Road,

Jianhu, Yancheng, Jiangsu, P.R.C.

Jiangsu Fiber Composite Co., Ltd. Nanjing Branch

Tel: +86 -025-86798609

MP +86-139-0518-7818

Web:www.jsfiberwell.com

Mail:alex@jsfiberwell.com

P.C.:210012

Add: Room G-712, Zendai Himalaya Centre, No 10 Minzhi Rd, Nanjing, Jiangsu, P.R.C.